Leading the Charge in Sustainable Food Processing

SCO2 is at the forefront of a new era in sustainable food processing, where food waste is no longer seen as a burden but as an opportunity. By harnessing the power of supercritical CO2 technology, SCO2 is pioneering innovative methods to upcycle food and agricultural waste into valuable resources. This transformative approach not only mitigates the environmental impact of waste but also creates new revenue opportunities for industries traditionally challenged by disposal costs.

In collaboration with major industry players, SCO2 is proving that sustainability and profitability can go hand in hand. Their unique licensing model and scalable technology are poised to revolutionize how the world handles food waste, positioning SCO2 as a leader in the global movement toward a more sustainable future.

We recently connected with Michael Sigel, CEO of SCO2, to explore the company’s journey, the evolving landscape of food waste management, and how their partnership with Avisen Legal has been critical in navigating the complexities of this innovative industry.

Can you share more about the origin of SCO2 and what inspired its mission to upcycle food and agricultural waste?

My background is predominantly in the food industry. I’ve been involved in the cheese business, baby food, and more recently, a functional beverage business that I helped turn around. We produced two-ounce probiotic juice shots and had a significant amount of byproduct, like citrus peel and pulp. We were committed to running a zero-waste facility, so our next best option was composting, but we were looking for something better.

I met Olaf Lee, one of SCO2’s founders, to explore using his technology as an alternative way of pasteurizing our juice (a method recognized by the FDA as an effective way to kill pathogens). Initially, I didn’t fully understand the technology, but clearly saw that Olaf is a brilliant guy. I left the juice company after successfully turning it around, and soon reconnected with Olaf. After meeting with him and seeing the issued patent for SCO2, I realized something significant was happening, even if I didn’t fully grasp it at first. Olaf’s background in the waste and recycling industry, combined with the technology they were developing, intrigued me.

We decided to join forces to see where we could aim the technology for the most impact. We started by really trying to understand how much better the SCO2 system was versus traditional methods where supercritical CO2 is used in high-value applications, like THC and CBD extraction, because it’s an effective, green tech.

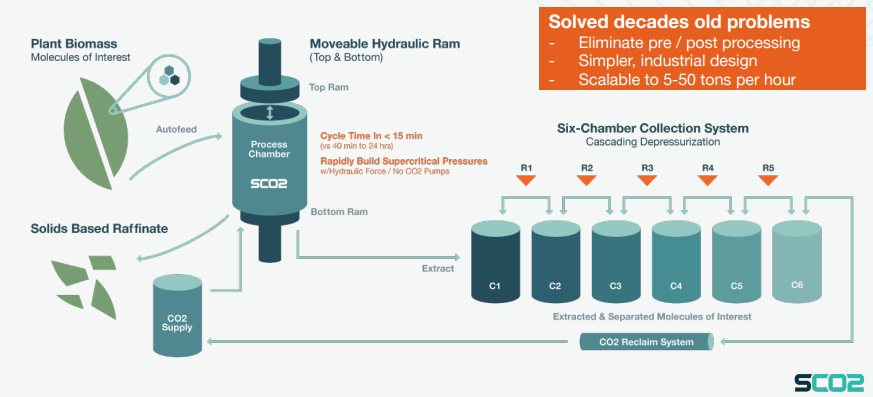

However, the challenge has always been scaling this process to an industrial level due to inefficiencies. Our patent solves these challenges, allowing us to scale the process to handle five to fifty tons an hour, which wasn’t feasible before. This breakthrough opens opportunities for addressing the massive global problem of food waste, particularly for growers and processors of everyday goods (nuts, olive oil, wine, fruit juices, etc.).

Now, we’re working on pilots with companies like POM Wonderful and Ferrero Chocolate to minimize waste and generate more value. The response from potential clients, especially those familiar with supercritical CO2 processing, has been overwhelmingly positive. They see this as a transformative technology that allows them to reconsider supercritical CO2 for large-scale applications.

The goal is to convert waste before it becomes a problem, keeping it out of landfills where it would generate harmful methane gas. With our technology, we can now tackle hundreds of feedstocks across various industries, making a real impact.

Could you describe how the technology works and how it redefines sustainable food waste management?

Traditional supercritical CO2 processes have 10-12 distinct steps to achieve extraction and separation to produce pure isolates or specific compounds. These are time-consuming, manual steps with each one requiring specialized equipment. SCO2 was essentially designed around these challenges to make a simpler, more cost-effective process that could scale economically. The result is an automated process (infeed and outfeed) and an ability to directly separate compounds to near isolate purity directly out of extraction.

There are some critical elements to an industrial process like ease of operation, 24×7 run durability for maximum up time, and low repair & maintenance needs. In addition, using simple design principles with primarily ‘off the shelf parts’ keeps costs relatively low. SCO2’s patents cover both the design and utility of the technology in truly novel ways compared to traditional systems.

What are some success stories or notable impacts from using SCO2’s technology?

There are a couple of interesting examples. One that stands out is with a hops farmer who was our first pilot customer. For them, growing revenue meant adding more acreage, which is expensive and risky given the variability in weather, soil, pest mitigation, etc. – all of which can directly impact yield.

This farmer came to us because their clients, craft brewers, were losing about 15-17% of their yield every time they brewed. The hops they were using would soak up a lot of the beer, leading to losses. Additionally, they had to deal with filtration, refrigeration, freight costs, and disposal costs, making the process inefficient.

The farmer had a specific hop terpene profile that could allow brewers more precision in their craft brewing. We offered them a way to convert their hops into highly concentrated hop terpenes with very specific characteristics. The idea is to help both the farmer and the craft brewer by eliminating waste, lowering the cost of transportation, refrigerated storage & handling, and improving their yield on each batch.

Another example is Bush Boy Farms, a local company with 48 acres of greenhouse space where they grow tomatoes, strawberries, cucumbers, and peppers. They have a lot of trimmings and vines that are typically hauled off site to be composted or landfilled. We’re working with them on a joint R&D project to extract valuable compounds from their wasted biomass and deliver an entirely new revenue stream while saving on disposal costs. Bushel Boy is already a very sustainable company. SCO2 technology represents a way to do even more for the planet and generate incremental revenue and profit at the same time.

How has Todd Taylor from Avisen Legal helped SCO2 with your business and legal needs?

Todd Taylor and the whole Avisen team really understand the needs of early-stage entrepreneurial ventures. They’ve had our back in helping us understand what we need to do to ensure we’re both protected and prepared, especially when it comes to agreements.

For example, just becoming a supplier for one of our clients, Ferrero Chocolate Company, came with a whole host of required documentation. Startups and large corporations don’t always work well together, but Todd helped us navigate the terms and conditions and proposed the agreement we ultimately got signed. Without Avisen’s help, the process would likely have been more complicated and would have taken much longer. Avisen is a strategic partner who helps us make sure we are protected. Todd and the team have a wealth of experience with companies at our stage which is important because they can help service and anticipate our needs.

What are the next projects or goals for SCO2?

The number one priority right now is raising money. We’re in the process of raising a $2.5 million seed round, and we’ve already secured $600,000. Our goal is to close this out in the next few months. After that, it’s all about delivering for our customers. We have nearly 10 projects in the pipeline and need to build out the team and our capacity in order to service even more customers.

What trends do you see shaping the future of food waste upcycling and sustainable food processing and how is SCO2 adapting to those trends?

Our customers see these trends firsthand. They’re under pressure from their customers—think Walmart, Amazon, Target, and every major grocery chain—who are saying, “You need to do more, and you need to do it faster.” Until about five years ago in the U.S., waste was just considered waste. Landfilling in the US is common. We have the land here and have a bit of an ‘out of sight, out of mind’ mentality. Europe, on the other hand, has been ahead of the curve because they don’t have the land for landfills, so mitigating waste has always been more pressing there.

Now, the situation is changing. Consumers are starting to vote with their wallets, and transparency is becoming more critical. Policymakers at the local, regional, state, and federal levels are also cracking down on waste streams. Practices like burying or burning waste are no longer acceptable, and our clients are feeling the pressure from these regulations.

As for how we fit into this trend, we’ve been recognized globally as one of 15 upcycling technologies likely to have the greatest impact. This recognition is largely due to the scalability of our solution. We’re actively working to build awareness about our technology and push it forward. We’re actively seeking partnerships, customers, and investors who can help us accelerate our impact.

In three to five years, when we have many SCO2 systems implemented around the globe, the impact will be significant. Globally, we waste about 1 trillion tons of food across the supply chain – farms, processors, distributors, retailers, restaurants, and our homes. About 20% of that comes from farms and processers, which is the segment SCO2 is focused on. We see a path to cutting this segment of waste in half (reducing 100 million tons per year). That alone is more than 1% of global greenhouse gases.

SCO2 Technology is likely to go through a typical adoption curve. Today, we are catering to early adopters. But it won’t take long to bring in the early majority and majority to turbo charge SCO2’s growth and overall impact.

Based on your experience, what advice would you give to other companies looking for legal support in this industry, and why should they consider working with the team at Avisen Legal?

I think Avisen Legal is a great solution for early-stage and fast-growing companies that don’t have internal legal counsel because of their unique blend of legal and entrepreneurial experience. Especially when your business is getting started, I think it’s all about matchmaking. You need to align yourself with a firm that’s right for where you are today and can grow with you. A good firm will let you know if they’re not the right fit for a particular aspect of your business, but they’ll still advocate for you and help guide you.

My advice is to start by getting a referral, then interview a few firms, and choose the one that feels like the right match. It’s an important relationship, and you want to feel confident that you’re covered in all aspects of your business. You should rely on a great partner who will be there for you over the long term. You need someone who will advocate for you, watch your back, and help you think through things you might not even know to consider.

To learn more about SCO2, connect with Michael Sigel, CEO, at michael@sco2.com.